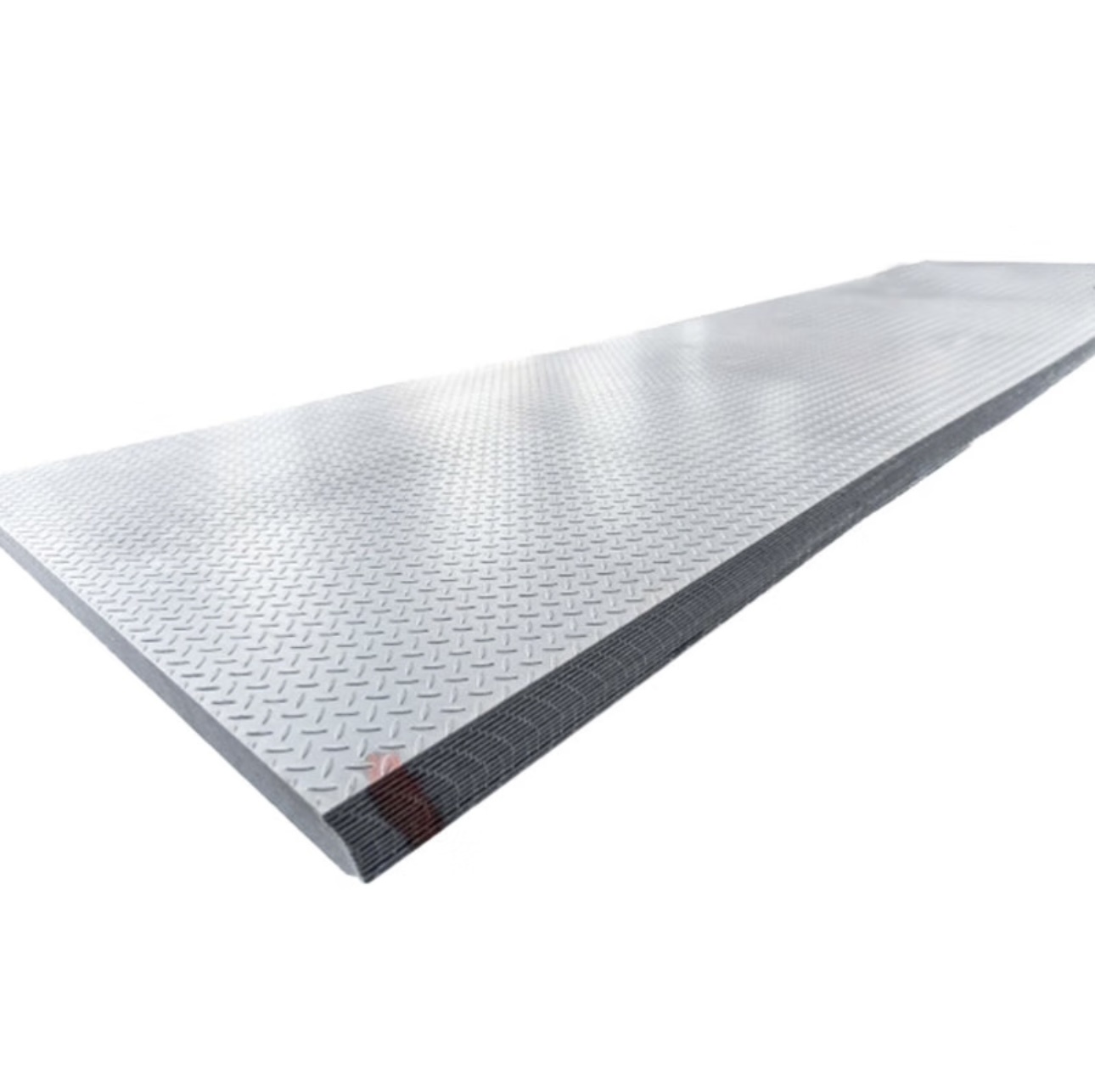

In hot rolling process, the billet is heated and rolled to form flat steel, which has good toughness, can be processed and has various sizes.

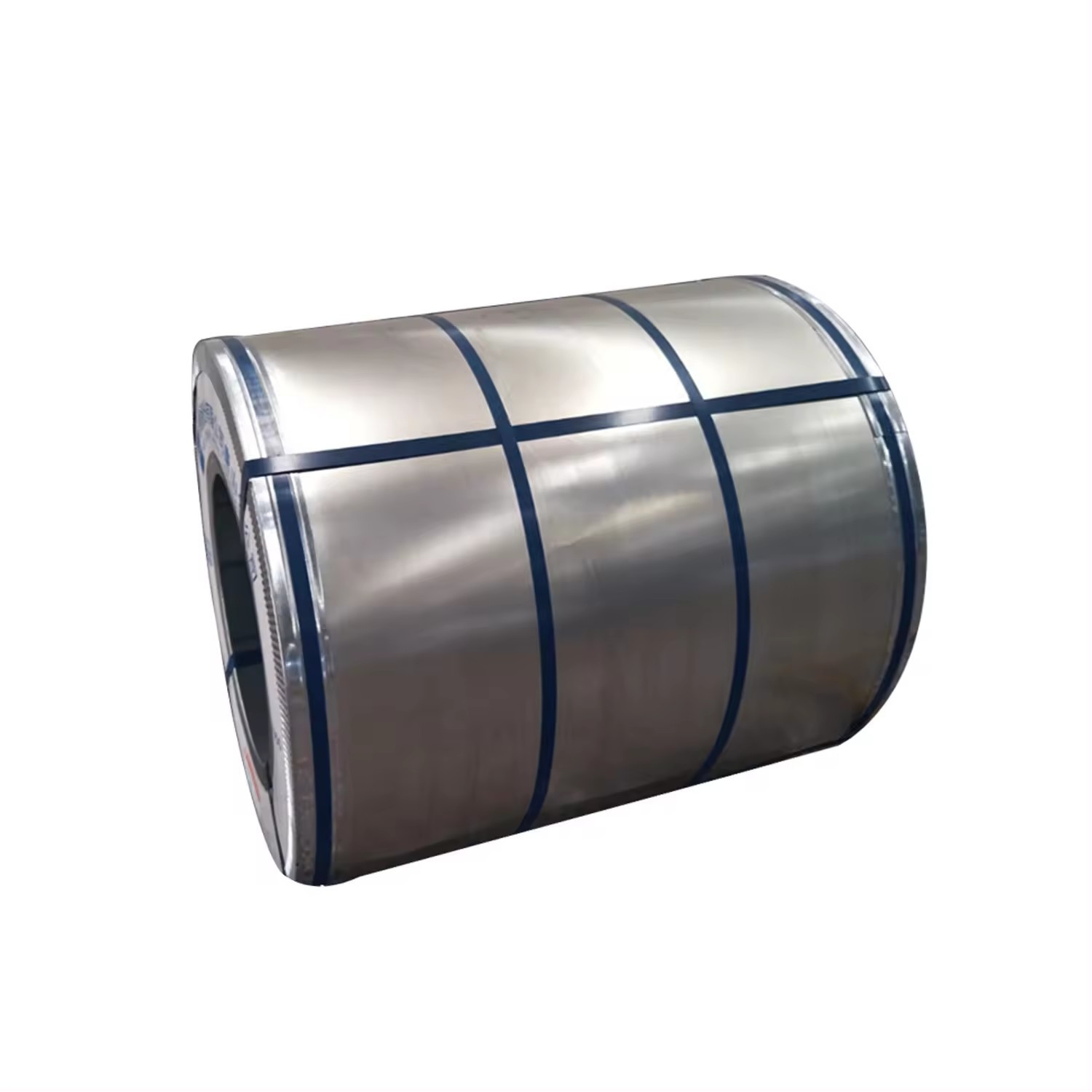

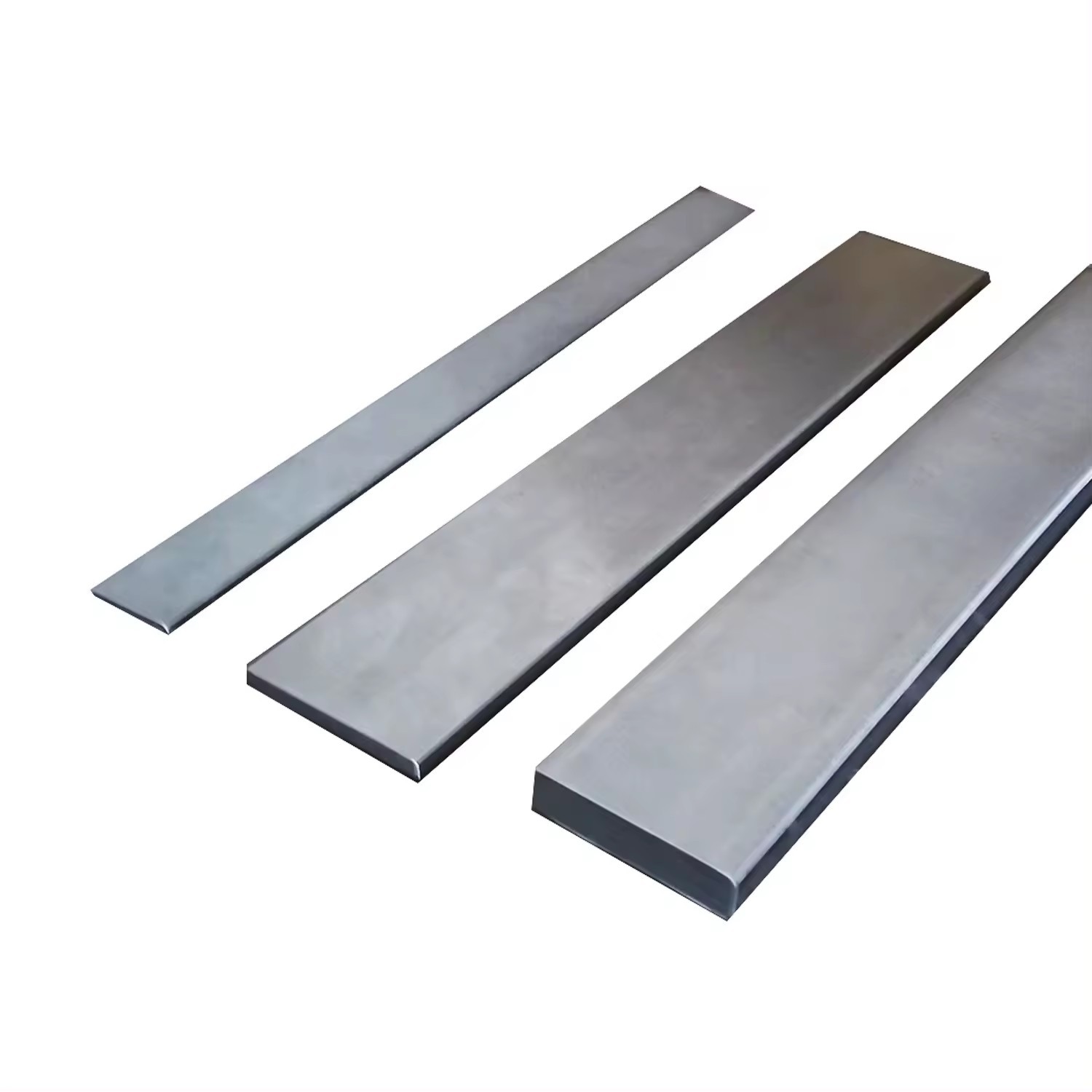

From the production process point of view, it is mainly through the method of hot dip galvanizing or electric galvanizing to form a uniform zinc layer on the surface of flat steel.

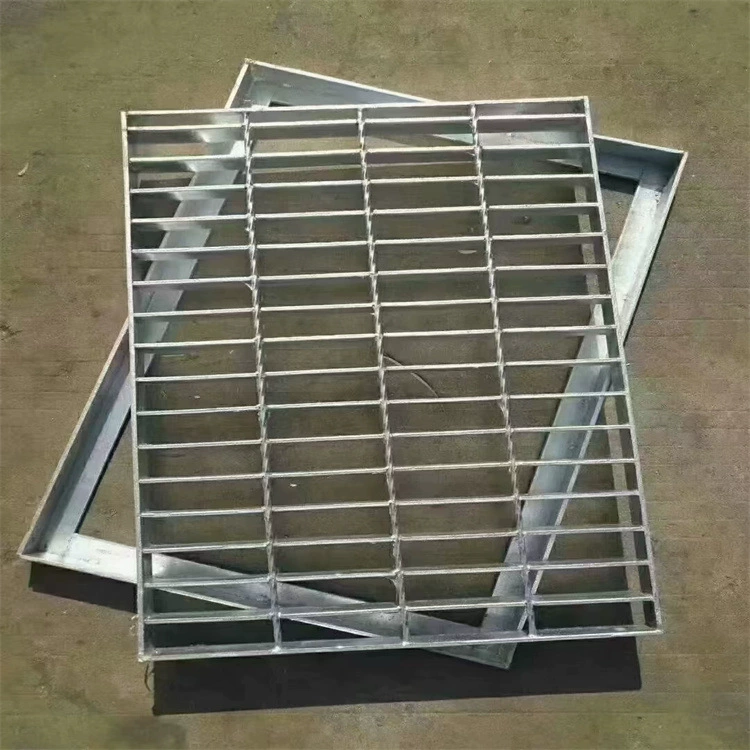

Galvanized grating is a common and widely used building material. The following is a detailed introduction for you:Definition and ProductionGalvanized grating is a material that enhances its corrosion resistance by coating a zinc layer on the surface of steel grating. It is usually made by arranging flat steel at regular intervals and intersecting with crossbars, and then welding them into a steel product with square grids in the middle. The crossbars are generally made of twisted square steel or flat steel. Its manufacturing process mainly includes raw material preparation, cold drawing, laser cutting, automatic welding, hot - dip galvanizing and other processes. Hot - dip galvanizing involves immersing the cleaned and activated steel products to be galvanized in molten zinc liquid. Through the reaction and diffusion between iron and zinc, a well - adhered zinc alloy coating is plated on the surface of the steel products.FeaturesStrong corrosion resistance: The zinc coating on the surface can effectively prevent the steel from contacting the external environment, avoiding the rust and corrosion of the grating. It can be used in harsh environments such as humid and acid - alkali for a long time. In a general natural environment, its service life is 40 - 50 years; in an acid - alkali industrial environment, the service life is 20 - 30 years.High strength: Made of high - strength steel and processed through processes such as cold bending, welding and hot - dip galvanizing, it has high strength and rigidity, can withstand heavy loads and resist impacts, and has good bearing capacity. In particular, the grating with a bar spacing of 50 mm has strong lateral impact resistance. The hot - dip galvanized steel grating with a flat steel spacing of 3 cm has a large impact resistance and the characteristic of a large span.Good anti - slip performance: The surface is designed with notches or protrusions, or the meshes are regular, which can effectively increase the anti - slip performance and ensure the safety of people walking.Aesthetically pleasing: It has a bright and smooth appearance. After surface treatment, it presents a metallic texture, with simple lines and a standard design, giving a modern and smooth overall feeling. It can be used for building decoration to enhance the aesthetics.Other features: It has the characteristics of ventilation and light transmission, facilitating air circulation and light penetration. It is also wear - resistant, easy to clean and simple to install. During installation, welding is not required, and it can be completed with simple tools such as bolts. In addition, kick plates (side plates), templates, accessory plates, etc. can be added as needed, and handles and hinges can also be installed. Different specifications, sizes and external dimensions can be customized according to customer requirements.Application FieldsIndustrial field: Widely used in industries such as petroleum, chemical, power generation, metallurgy, papermaking and environmental protection. It can be used for platforms, operating platforms, shelves, stairs, passages, filters, sidewalks, sewage ditches, equipment protection covers, etc. in factories, workshops, docks, warehouses and other places. It can withstand heavy pressure and the erosion of chemical substances, providing a safe and reliable working environment.Building field: Commonly used in parts of buildings such as stair steps, platforms, railings, doors and windows, roofs, exterior walls, overpasses and porches. It is both beautiful and can increase the overall stability and durability of the building. It can also be used in the underground drainage and ventilation systems.Transportation field: Used as guardrails, guardrail plates, sidewalks, pedestrian overpasses, drainage ditch covers, etc. for bridges, roads, highways, railways, airports, etc., to ensure the stability and safety of transportation facilities. It can also be used on ship decks and docks to adapt to the complex conditions of the water environment.Municipal engineering: As road drainage facilities, gratings for sewage treatment equipment, protective fences, rainwater manhole covers, sidewalks, park flower bed fences, etc., to ensure the function and service life of the facilities.Civil field: It can be used for balconies, stairs, sewage manhole covers, drainage ditch covers, etc. in residential areas. It has a good anti - slip effect, can prevent pedestrians from slipping, and is both beautiful and practical. The toothed grating is also suitable for residential areas with a large flow of people, as well as the presence of the elderly and children.Agricultural field: It can be used as slope protection plates and drainage ditch covers for farmland water conservancy projects, as well as fences and isolation facilities in agricultural greenhouses, livestock and poultry farms and other places. It has the characteristics of corrosion resistance, anti - slip and pressure resistance, and can ad

Galvanized Slitting Flat Steel is made by galvanizing flat steel through slitting process. In terms of characteristics, the galvanized layer gives it good corrosion resistance, which effectively prevents the flat steel from being oxidized and maintains its performance for a long time even under complex environmental conditions.

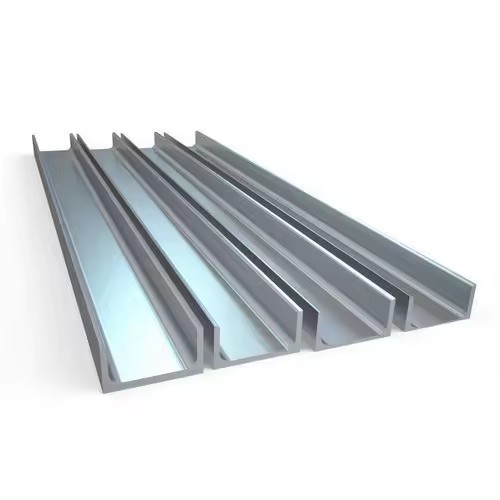

Galvanized channel steel mainly has the following characteristics. In terms of material, it is a kind of long steel with a groove-shaped cross-section and a zinc coating on its surface. Its galvanized layer makes it has good corrosion resistance, can effectively resist the air moisture, acid and alkali substances on the steel erosion, prolong the service life.

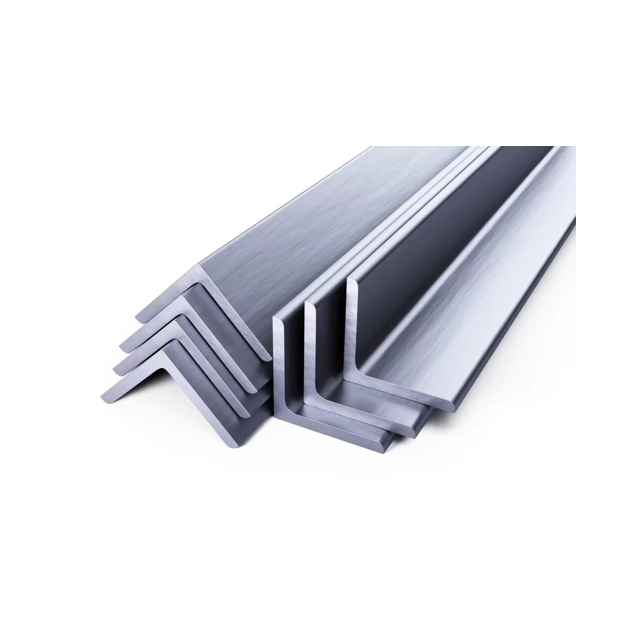

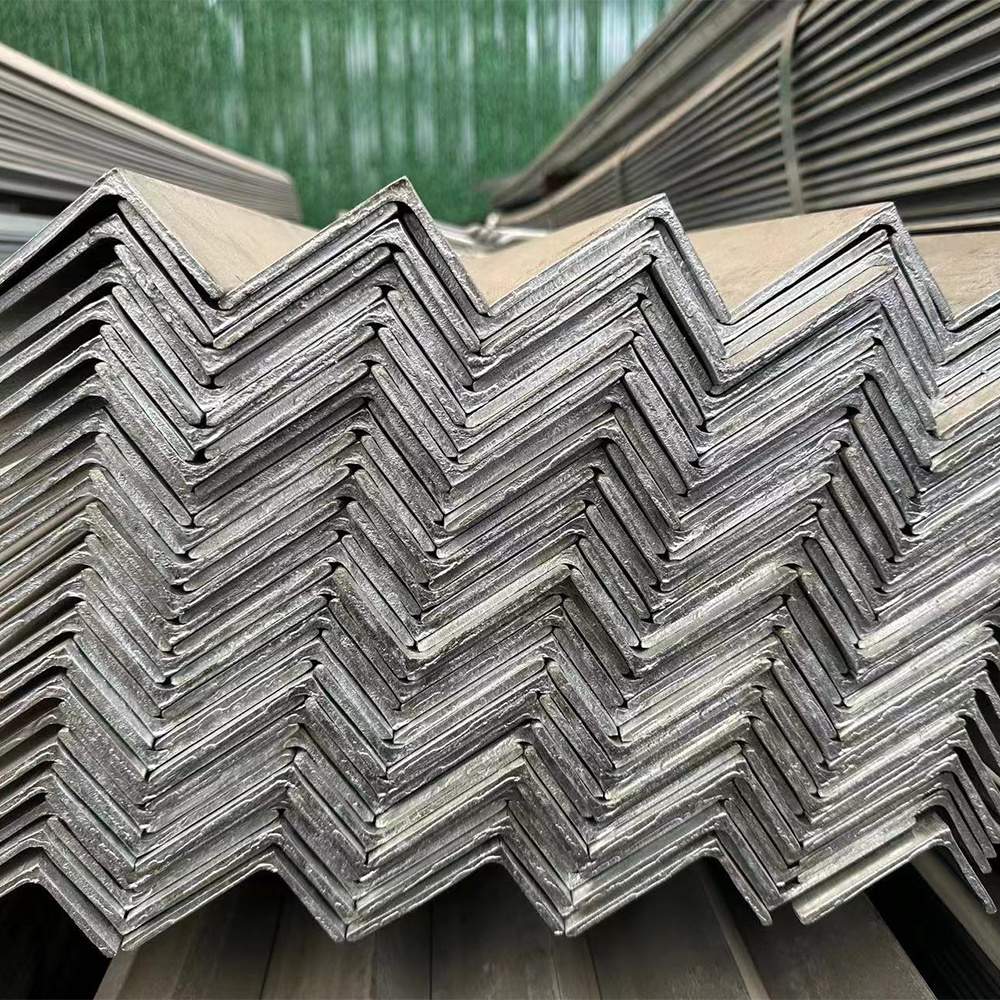

Galvanized Angle steel is a galvanized Angle steel that plays a key role in many fields such as construction and manufacturing.

Galvanized Hot Rolled Flat Steel

The shape of the I-steel is similar to the Chinese character "gong", which is a long steel bar with an I-shaped cross section.

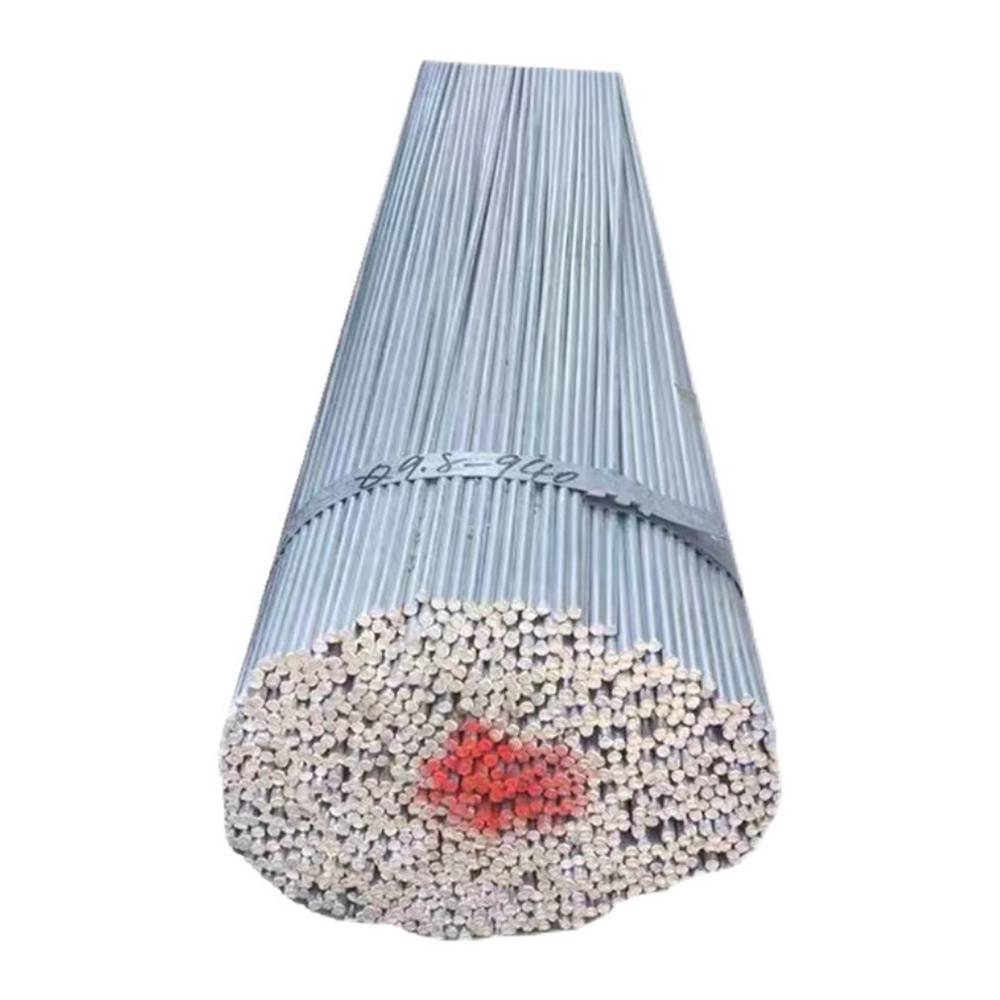

The galvanized layer on the surface of galvanized round steel provides excellent corrosion resistance, which can effectively prevent the round steel from rusting and keep it in good condition in wet and corrosive environments. In appearance, galvanized round steel has a bright color and is more beautiful. In terms of material properties, round steel itself has good toughness and strength, can withstand certain tensile, bending and other forces.

Galvanized grating plate is a kind of metal plate which is arranged by flat steel and cross bar in accordance with certain spacing and has been galvanized.

Galvanized Unequal Angle Steel

Galvanized unequal angle is a special type of steel section.

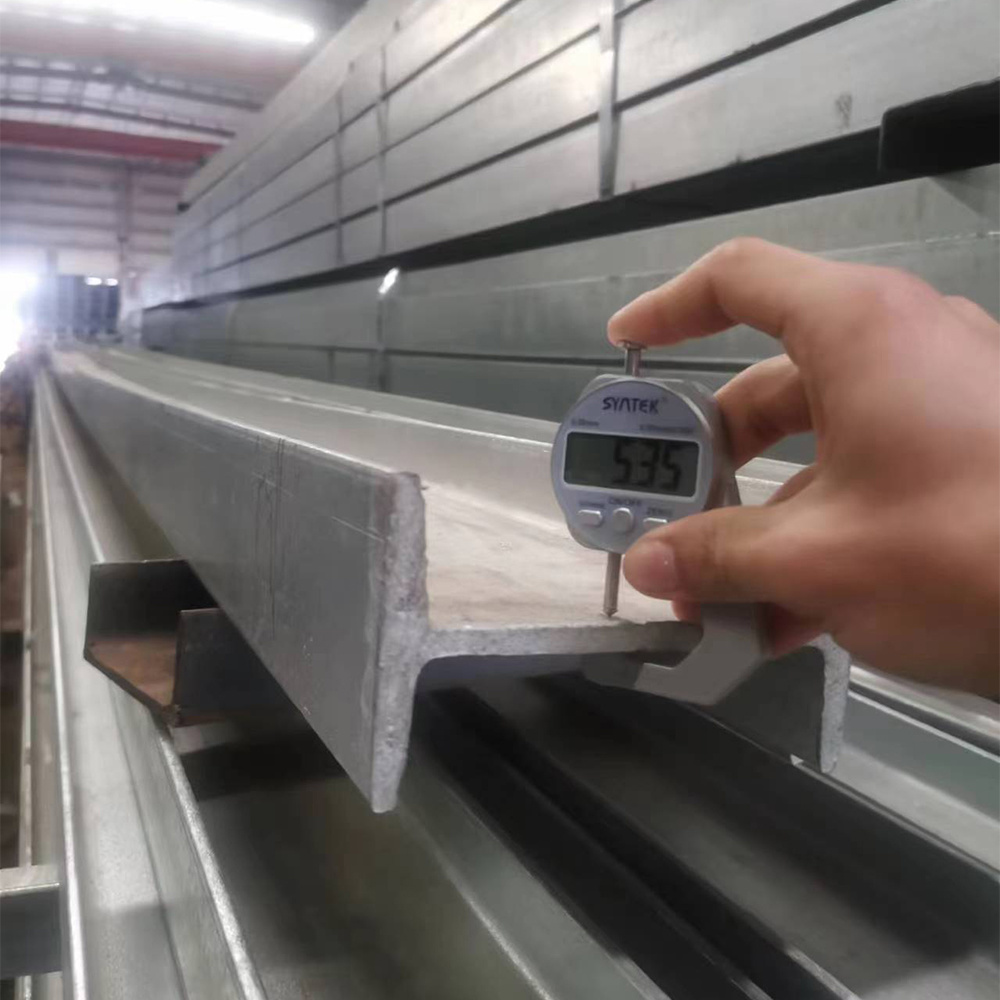

Galvanized I-beams are a type of steel with an I-beam cross-section, and the zinc coating on the surface is a key advantage. This layer of zinc greatly enhances the corrosion resistance of the I-beam, making it resistant to acid rain, humid air and other harsh environmental factors, as well as having a brighter appearance.

Galvanized H-beam steel from the appearance, its cross-section shape is “H” shape, the structure is regular. Its galvanized layer is an important protective layer with excellent corrosion resistance, which can effectively resist the erosion of air, moisture and chemicals and prolong the service life of the steel, and the surface is smooth and beautiful after galvanization.